TRAY SEALERs

semi-automatic

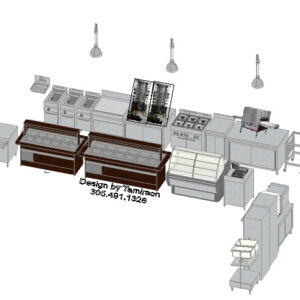

Model │ TS-30

Tray Sealer, electric, semi-automatic, 13-9/10"W x 11-1/5"D x 4-1/2"H tray capacity, up to 19-1/2" web, 40m³ Busch pump, vacuum sensor, MC-40 microprocessor, touch screen, M.A.P. gas injection, automatic sealing, cutting of film & trim rewinding, quick change dies, crate, aluminum casting chambers, stainless steel construction, adjustable legs, CSA – 40m(3) Busch Pump, 2 HP, standard.

208-220v/60/3-ph, standard

SALE PRICE $31,180 PLUS $1250 FRIGHT

Versatility

The tray sealer is for food

products and for industrial and

medical supply packaging.

Flexibility

These machines can be

adapted to all tray sizes.

High-performance

Automatic tray sealers come with modified

atmosphere packaging (MAP) to increases

the product’s shelf life, provides extra

protection, prevents colouring.

Easy maintenance

Heavy-duty, reliable stainless steel

and easily dismantled components

ensure the best possible maintenance

processes.

Why should you use

a tray sealer ?

To avoid crushing delicate food items;

To preserve freshness;

To increase the shelf life of food products;

To prevent dehydration;

For easier handling;

To slow oxidation;

To protect against external contamination;

To package products in preformed

trays of different shapes and sizes.

Model TS-30

Machine

dimensions

Length A 33” (834 mm)

Width B 43” (1,105 mm)

Height C 63” (1,605 mm)

Production

capacity 2-3 cycles / min. (MAP)

MAx. DIMENSIONS

of trays

Length A 13.9” (353 mm)

Width B 11.2” (284 mm)

Height C 4.5” (114 mm)

power supply 208-220 V / 3 pH / 60 Hz

Pump capacity (STD) 40 m3 2.0 HP

Max. Film width 19.5” (495 mm)

MICROPROCESSOR Touch Screen

Multi Size Trays Options Maximum Size of Tray – 13.9” left to right – 11” front to back & 4” deep

and so much more

Reviews

There are no reviews yet.