Glyco – Glycol Pak "Water Tower"

Delivered anywhere in The USA / Installed In Florida

Water Cooled Yogurt Ice Cream Machines / Ice Machines & More- Closed Loop Fluid Cooled Machines Plus Glycol.

For More Information Call sammy At 305.4891.1326 or email us at info@tamirson.com

Glycol-Pak-GP-6 $8500 plus $750 drop ship-900lb

Glycol-Pak-GP-1 $4250 plus $375 drop ship-450lb

|

Sealed-in closed-loop propylene-glycol water cooling remote systems for Soft-Serve machines that are sure to dramatically lower costs while upping efficiency. Ruggedly constructed Glycol-Packs are completely unitized at the factory including fluid manifolds and piping/wiring. Typical total Payback-on Investment in under One Year.

|

Call Or Email Us for the model # you need

|

Airdyne Model No.

|

No. of Soft-Serve Barrels

|

Heat of *Rejection (BTU)

|

Total Fluid Volume (GAL)

|

Fluid Flow (GPM)

|

Hot Fluid (Inlet)

|

Cold Fluid (Outlet)

|

L

|

W

|

H

|

Total System AMPS**

|

Shipping Weigth (LBS)

|

|

GP-1

|

2

|

30,000

|

4

|

4

|

7/8"

|

7/8"

|

30

|

22

|

36

|

5.7

|

300

|

|

GP-2

|

4

|

55,000

|

6

|

8

|

1 1/8"

|

1 1/8"

|

50

|

22

|

36

|

7.5

|

400

|

|

GP-3

|

6

|

81,000

|

8

|

10

|

1 1/8"

|

1 1/8"

|

50

|

22

|

36

|

9.1

|

500

|

|

GP-4

|

8

|

108,000

|

10

|

13

|

1 3/8"

|

1 3/8"

|

70

|

22

|

36

|

12.7

|

600

|

|

GP-5

|

10

|

135,000

|

12

|

16

|

1 5/8"

|

1 5/8"

|

90

|

22

|

36

|

14.5

|

700

|

|

GP-6

|

12

|

165,000

|

14

|

20

|

1 5/8"

|

1 5/8"

|

110

|

22

|

36

|

18.2

|

900

|

|

GP-7

|

14

|

190,000

|

15

|

22

|

1 5/8"

|

1 5/8"

|

70

|

60

|

36

|

22.2

|

1200

|

|

GP-8

|

16

|

225,000

|

16

|

25

|

1 5/8"

|

1 5/8"

|

70

|

60

|

36

|

22.2

|

1225

|

|

GP-9

|

18

|

260,000

|

18

|

29

|

1 5/8"

|

1 5/8"

|

70

|

60

|

36

|

22.2

|

1250

|

|

GP-10

|

20

|

290,000

|

22

|

32

|

2 1/8"

|

2 1/8"

|

90

|

60

|

36

|

27.9

|

1400

|

|

GP-11

|

22

|

330,000

|

26

|

37

|

2 1/8"

|

2 1/8"

|

90

|

60

|

36

|

27.5

|

1400

|

|

GP-12

|

24

|

362,000

|

28

|

40

|

2 1/8"

|

2 1/8"

|

130

|

22

|

54

|

27.5

|

1800

|

|

GP-13

|

26

|

408,000

|

30

|

44

|

2 1/8"

|

2 1/8"

|

130

|

22

|

54

|

27.5

|

1800

|

NOTES: *Heat rejection is calculated at ambient temperature of 120 degrees Farenheit. **(208V/1 PH/60HZ)

|

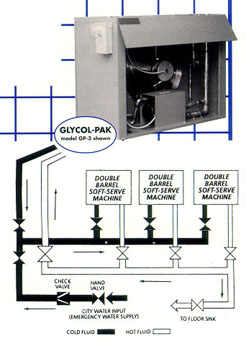

Fluid Cooling Systems for Soft-Serve Frozen Yogurt Freezers System Design The Airdyne GLYCOL-PAK: FLUID cooler is a heat exchanger designed to operate with water-cooled dispensing equipment. The hot glycol from the water-cooled condenser is piped to the GLYCOL-PAK fluid cooler, whereby heat is removed from the fluid and rejected into the outside air. The cooled glycol is re-circulated as required by the water-cooled equipment. The system is controlled by a thermostat to shut the fans off at a predetermined temperature on GP-4s and up. Fluid cooler is completely piped and pre-wired for low cost installation in the field. Benefits of Glycol-Pak The closed-loop glycol fluid cooling system’s benefits are twofold. The yogurt shop’s air conditioning load is reduced as the compressor heat is not rejected into the conditioned space. Features of the Glycol-Pak The system accommodates up to 12 barrels. Choice of six standard models available from 2 to 12 barrel soft-serve freezers for frozen yogurt/ice cream. |

GLYCOL-PAK FLUID COOLING SYSTEMS WITH PRE-COOLER

FOR SOFT SERVE FROZEN YOGURT FREEZERS

The AIRDYNE GLYCOL-PAK: fluid cooler with Pre-Cooler

is a heat exchanger designed to operate with water

cooled dispensing equipment. The hot glycol from the

water cooled condenser is piped to the GLYCOL-PAK

fluid cooler, whereby heat is removed from the fluid and

rejected into the outside air. The cooled glycol is recirculated

as required by the water cooled equipment.

The system is controlled by a thermostat to shut the fans

off at a predetermined temperature on GP-4s and up.

Fluid cooler is completely piped and pre-wired for low cost

installation in the field.

The yogurt shop’s air conditioning load is reduced as the

compressor heat is not rejected into the conditioned

space. The additional benefit is the dramatic savings in

the water usage thus reducing the water and sewer bills.

The cooled glycol is re-circulated in a closed loop circuit

and never comes into contact with the outside air. There

is no need for adding makeup water or the expensive

maintenance and chemicals typical of open type cooling

systems.

In dry heat ambient conditions over 110°F. The glycol

returned to the yogurt machines is designed to go off on

high head pressure as 95° glycol is not enough to cool the

machines and compressor may shut down causing soft

serve machines to dispense runny yogurt. In dry heat we

recommend using a Pre-Cooler as it enables the Glycol-

Pak system to drop the glycol temperature down another

10° which keeps the compressor running in hot ambient

conditions.

The system accommodates up to 12 barrels. Customer

has a Choice of six standard models available from 2 to

barrel soft-serve freezers for frozen yogurt/ice cream.

Each system is equipped with a durable galvanized

cabinet, staggered copper tube coils with aluminum fins,

centrifugal pump, fan motor assembly, thermal expansion

tank with fill port, pump bypass with adjustable pressure

relief valve, automatic air venting valve, fan cycle

thermostat; for GP-4 & up, main fuse disconnect and fluid

manifolds.

NOTES: *Heat rejection is calculated at ambient temperature of 120° degrees Fahrenheit. ** (208 Volts, Single Phase, and 60 Hertz)No.BarrelsBTU)Total FluiVolumeluiConne

GP-1SC 2 30,000 4 4 7/8” 7/8” 30 68 36 13.2 500

GP-2SC 4 55,000 6 8 1 1/8” 1 1/8” 50 68 36 15 600

GP-3SC 6 81,000 8 10 1 1/8” 1 18” 50 68 36 15.3 700

GP-4SC 8 108,000 10 13 1 3/8” 1 3/8” 70 68 36 19.6 800

GP-5SC 10 135,000 12 16 1 5/8” 1 5/8” 90 68 36 24 985

GP-6SC 12 165,000 14 20 1 5/8” 1 5/8” 90 68 36 28.3 1100

GP-7SC 14 190,000 15 22 1 5/8” 1 5/8” 90 60 72 28.3 1300

GP-8SC 16 225,000 16 25 1 5/8” 1 5/8” 70 60 72 28.3 1425

GP-9SC 18 260,000 18 29 1 5/8” 1 5/8” 70 60 72 28.3 1450