|

| *************************************** |

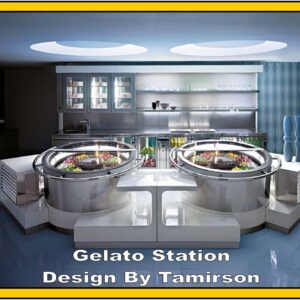

Perfect preservation of product quality and flavor…continuous failure-free operation that virtually eliminates maintenance…absolute minimum of operating costs…these are the advantages offered by Nelson’s superior design and construction which can only be measured over long periods in terms of service and value. Since 1898, the industry’s finest equipment for the protection of quality and flavor in ice cream and frozen foods.

Our cabinets have more insulation than most other ice cream freezers- 2-1/2" of insulation on the sidewall. This feature means lower operating costs than our competitors.

We offer the largest selection in the industry, all in a standard white enamel finish or optional stainless interior,exterior or both. All cabinets equipment with digital thermostats, clog-free condensing units and optional features such as locking devises, legs or casters.

Our ice cream cabinets are also available with raised-bottom freezers for those operators who do not use the lower step in a conventional freezer. The cabinets can be made with optional dry storage in the lower area. Operationally, there is no need to have empty tubs or milk crates or whatever to raise your ice cream containers. And no lower area to clean or pay to refrigerate if you don’t ever use. And you don’t have to bend over so far. My back feels better already.

Nelson Ice Cream Dippiong Cabineis, Best Deal online.

IMPORTANT NOTES:NSF STANDARDS REQUIRE CABINET TO BE INSTALLED WITH CASTERS, 6” LEGS, OR SEALED TO THE FLOOR WITH AN NSF APPROVED SILICONE SEALANT AT THE TIME OF INSTALLATION.

SPECIFICATIONS

- One piece 22 ga. 304 stainless steel, all corners welded (no corner pieces or raw edges, ever).

- Galvanized steel reinforced sub-top beneath the stainless top, Anti-condensate heater wires on galvanized sub-top to prevent condensation on cabinet top.

- 24 ga stainless steel interior, Optional 22 ga. 304 stainless steel exterior.

- Copper tubing cold wall type evaporator attached to liner wall.

- Forced air condensing unit (clog free design on all BD models) on glide-out base for efficient operation and built-in applications.

- Base of cabinet to be constructed of 16 ga. Galvanized steel.

- Poured-in place urethane foam insulation with a minimum "K" factor of .13.

- Lids to be stainless steel top with poured urethane foam insulation and hinged in the center with rubber handles.

- Freezer lid gaskets to be of a molded, one piece, high impact grade ABS plastic.

- Cabinet to be equipped with a 7-ft power cord, 3 wire, grounded, dead front construction.

- Unit to be NSF & ETL approved.

|

Specifications |

BD4 |

BD6 |

BD8 |

BD10 |

BD12 |

BD14 |

BS2 |

BS4 |

|

SHIP WT. |

225 |

275 |

315 |

375 |

430 |

460 |

175 |

240 |

|

CuFt CAPACITY |

8.0 |

13 |

17.5 |

22.5 |

27.5 |

29.5 |

4.8 |

10.5 |

|

NBR FACINGS |

5 |

7 |

10 |

12 |

14 |

16 |

2 |

5 |

|

TOTAL NBR TUBS |

8 |

13 |

17 |

22 |

27 |

29 |

4 |

9 |

|

COMPRESSOR |

1/3 hp |

1/3 hp |

1/3 hp |

1/3 hp |

Sm 1/2 hp |

Sm 1/2 hp |

1/5 hp |

1/5 hp |

|

AMPS |

8 |

8 |

8 |

8 |

11 |

11 |

5 |

5 |

|

ELECTRIC |

115 v. |

115v. |

115v |

115v |

115v |

115v |

115v |

115v |

Reviews

There are no reviews yet.